1950

- Foundation of BRINKMANN PUMPEN by Karl-Heinz Brinkmann at Werdohl-Kleinhammer.

- Even after a short period, there was a wide range of pumps.

As one of the competence leaders in our industry, we have been shaping progress under the BRINKMANN PUMPS brand – for 75 years. We think ahead – in solutions and across borders. We meet challenges with our well-known innovative strength. In the search for new solutions, we act openly, transparently and always with commitment. On this basis, we offer our customers sophisticated pumps, motors and smart solutions for a digitally networked, climate-neutral and globalized industry. Real quality products "Made in Germany".

As a dynamic family-owned company, we have extensive entrepreneurial freedom and enjoy a high level of trust among our customers, suppliers and employees. Our strong brand offers the best conditions for top performance. The perfectly fitting combination of flat hierarchies, short coordination paths and largely automated production also opens up flexible options for us to meet customer requirements quickly and in a targeted manner.

A respectful, open and fair treatment of all people is a tradition at BRINKMANN PUMPS. We are committed to upholding human rights, respecting the dignity of the individual and, in particular, safeguarding the rights of children. We take into account the scarcity of natural resources and the resulting social responsibility with our actions every day.

Our path to the future is clearly defined. We are already using our development expertise and many other options to develop technologies in line with the Industry 4.0 standard. We have been pursuing this path consistently and energetically for some time now. The aim of future efforts is to offer our customers sophisticated solutions for a digitally networked and climate-neutral industry. By implementing appropriate structures, we are helping to shape modern industrial value chains that meet sustainability criteria. An accelerated exchange of data ensures more effective and efficient processes. It also expands the possibilities for responding quickly and flexibly to new requirements. At the same time, digitally networked systems make an important contribution to minimizing the emission of climate-warming greenhouse gases – and support industry on the path to climate neutrality.

With passion and great commitment, we do everything we can every day to make our customers' projects more successful with sophisticated pumps, motors and diverse applications. Smart products and services enable sustainable, industrial fluid applications for our customers around the world. As a technology leader, we use all the resources at our disposal to achieve these goals at the highest level. We bring all our know-how and experience from more than seven decades to the development of customized solutions. We maintain a communication style that is oriented toward the goal of the project and characterized by transparency, openness and commitment. With our understanding of productive pump solutions, top quality and fast responses, we have earned a reputation as a true problem solver in a wide range of industries.

Our thorough understanding of all technologies applied in the field in combination with our extensive experience and ability to innovate allows us to serve as a strategic partner and as a problem solver at the same time.

As a technology leader we are capable of thinking outside of the box in order to find new and ideal pump solutions. At the same time, we never lose focus of our current tasks at hand and feel always responsible to strive for the best possible solution while adding value for our customers.

On the basis of competent consulting we develop sound relationships with our customers which are exemplified by transparency and commitment.

Particularly during research and development projects with our customers we put strong emphasis on continuous and in-depth exchanges and communication with our customers to ensure the success of our engineering.

With intelligent engineering and our commitment to highest quality we create technically sophisticated products.

During the creation of customer specific solutions we count on the in-depth knowledge and experience of our engineering team in terms of pump technologies, electric motor design and application know-how.

The in-depth knowledge of all characteristics and behaviors of our materials of construction builds the basis for efficient and market oriented solutions.

Our modular hydraulic design system builds the basis for allowing us to precisely meet your specific application requirements.

Close interaction amongst our engineers, production and quality specialists in conjunction with high tech measuring and testing processes in accordance to latest ISO standards allows us to consistently generate high quality results at comparatively short development times.

Whether it is the selection of suppliers and materials or the continuous monitoring of production, at BRINKMANN, our own high quality requirements are reflected in the permanent monitoring of all ongoing processes and it also encompasses the strict monitoring of shipments and logistics.

BRINKMANN PUMPS is certified in accordance with quality management system EN ISO 9001. This testifies to the strict, demanding approach to quality which implemented in all departments throughout the company.

With our vast knowledge, experience and well trained personnel, we can support you during all stages of the purchase of our high quality pumps.

We provide you with all necessary support for selecting the pump that perfectly matches your requirements and we are here for you throughout the entire life cycle of the project.

We know that fast processing time is just as important for customer satisfaction as product quality. We will also impress you in this respect.

We are always available to answer any of your questions or give you the expert advice: in person, by phone or through our website.

1950

1950 until 1990

until 1990Continuous growth of the company forces a constant expansion of production capacity and the accompanying development of the company's premises

1991

1991 1993

1993The innovative quick suction immersible pumps with the patented "BRINKMANN suction de-aeration system" enables the efficient pumping of extremely inflated fluids.

1997

1997 2005

2005 2006

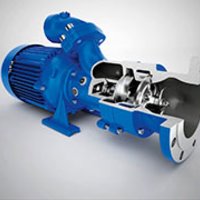

2006Introduction of horizontal end suction pumps characterised by a compact block design with the impeller on an extended motor shaft

2008

2008 2009

2009 2010

2010Werdohl hosts the first BRINKMANN PUMPS symposium. The theme of this event was "The contribution of energy efficient components in energy efficient machine tools".

2011

2011 2013

2013Market launch of cutter pumps for defined steel applications with a robust cutting mechanism

2014

2014 2015

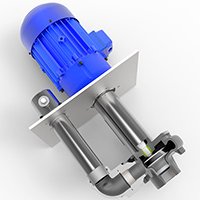

2015Expansion of the product range with self-priming end-suction pumps for quick suction from up to 5 m depth.

2017

2017 2018

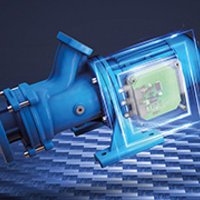

2018Start into the world of digitalization: Utilizing bplogic pump control allows to intelligently integrate BRINKMANN PUMPS' know how between machine tools, pumps, filtration systems and other components.

2022

2022